Easy Run – Rotomoulding Machine Control Software

9 October 2020

Main functions

The main functions of the system are:

- movement of the machine with punctual diagnostics of each component and of each movement to allow easy identification of faults and rapid restoration of machine functionality,

- process control with a wide range of configuration and work parameters that guarantee great flexibility in the management of the work cycle,

- complete, intuitive and ergonomic operator interface.

SCADA

In particular, the SCADA linked to the machine offers the following functions:

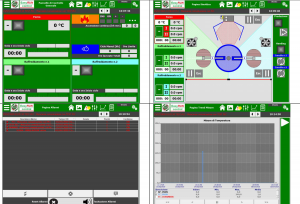

- animated graphic representation of various views of the machine,

- burner monitoring window,

- control panel of the process and active work cycles,

- preparation of work cycles with the possibility of configuring the heating of up to three layers of material with a cycle of up to four temperature steps and coling cycles with up to four steps for the combination of the use of forced air and nebulized water,

- modification in runtime of the working parameters of each active cycle,

- display of active alarms,

- historicization of alarms,

- graphic representation of the time course of each measurement (Temperature, Power supply, Instantaneous Power, Speed, Frequency) detected by the system,

- archiving of measured values,

- reporting on production progress with number of cycles performed and work parameters

used in the chosen time interval. - User management with access levels for different professionals (Operator, Process Engineer, Maintenance Technician, Systems Engineer, …)

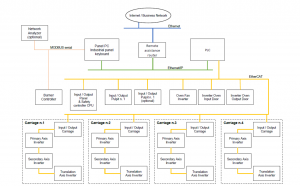

Monitoring and remote assistance

Because customer support is one of our priorities, remote connection to the system for remote assistance is provided.

As an option, it is also possible to to connect remotely to the system throught a web client for monitoring or

possibly even control purposes.